Casescase

CasescaseCoating process is widely used in automotive design, such as manual coating, positive mold blister, negative mold blister, slicing and PU spraying, etc. Today, we focus on introducing the manufacturing process and structure type of the lower coating process. Understanding these contents can effectively develop a reasonable block structure from the initial stage of design, and establish a solid foundation for the appearance quality assurance in the later stage.

1. Coating process

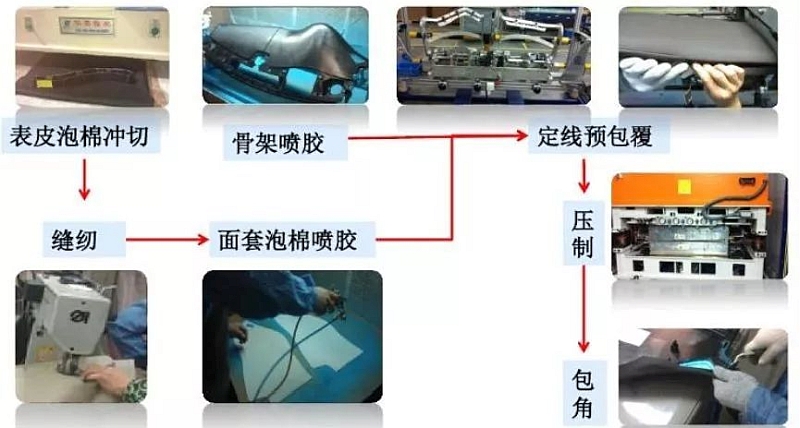

First of all, briefly understand the coating process of typical products. The main processes are punching, sewing, spraying, pre-coating, pressing and corner coating. The following is the coating schematic process of the body on the IP.

01 Cutting Process

Common punching process: manual drawing cutting, die punching, cutting bed cutting, etc. Under normal circumstances, if the cutting pieces have sewing needs, it is necessary to use the knife die punching or cutting bed to ensure the processing accuracy.

The difference in cutting accuracy is large, the knife die punching is ±0.5mm, the cutting bed is ±1mm, the manual is greater than 2mm, the production flexible manual is greater than the cutting bed is greater than the knife die punching.

02 Sewing Thread

Sewing thread is mainly divided into single stitch, double stitch, we mainly pay attention to the parallelism of the stitch, margin and needle distance requirements.

Due to the structural limitations of the sewing machine, there are clear restrictions on the distance between the suture line and the edge of the structure, the position of the needle point, the product structure, etc. The commonly used sewing parameters are as follows:

Stitching line: 10±0.5 stitches /25mm;

Decorative thread: 6±0.5 needle /25mm;

Double needle distance is generally 6, 8, 10mm, due to different sewing machine completion, can not be adjusted;

Minimum flattening width of double sewing thread 60mm, minimum flattening width of single sewing thread 20mm;

The minimum distance between stitches and edges is 14mm.

03 Glue

Common glue categories: solvent-based glue, water-soluble glue, hot melt glue, etc.

Commonly used solvent glue: neoprene adhesive with low material surface extreme demand, mainly used in PP materials, polyurethane adhesive with high surface polarity demand;

Coating processing conditions: depending on the characteristics of the glue.

The first principle of glue selection is to meet the odor and dispersion test requirements, neoprene glue can not be used on the test product above 105 ° C, and can not be applied to some PVC skin, otherwise it will occur adhesion failure. There is a certain anti-work phenomenon in manual coating, and the use of PU adhesive after PP skeleton flame treatment, easy to form a film, resulting in coating defects scrap.

04 Alignment process

Common alignment tooling structure: alignment knife or laser alignment, manual positioning of skeleton groove, matching positioning of the outer contour of the cutting piece and the die cavity, etc. We need to pay attention to the position of the suture, and the direction of movement of the tooling structure coincides with the normal direction of the product suture.

First, the skeleton was positioned in the lower fetal membrane, and the epidermis was positioned on the skeleton. Then, the alignment knife was pulled down to the set position, the epidermal suture position was adjusted to match the requirements, the alignment knife was lowered again to the fixed position, and other non-suture positions were covered.

05 Pressing process

Common pressing processes include pressure source contact molding, pressure pressing, etc. The heating source is constant temperature heating, external heating module, etc. The contact molding has no additional process edge and coating to meet the requirements of closed mold cavities.

2 Coating process block method

In the evaluation stage of the effect drawing, the structural segmentation should be determined in advance according to the CTF and project input, and a reasonable technical plan should be determined to prevent the forming process determined at the initial stage from reaching the expected appearance quality and machinability.

01 Three-side intersection structure

The structure shown below is very common in interior products. If the above effect cannot be achieved by manual coating without setting stitches, it can be considered as IMG process.

Of course, in the case of redefining the block or adding functional lines, manual wrapping can be achieved, the solution is as follows:

Method 1: Add the functional line of the surface partition

Method 2: Redefine product segmentation

02 Straight line structure, arc structure

Linear structure is more common, and properly controlled gaps generally do not cause problems.

The following figure shows the arc structure, there are two kinds of inner circle and outer circle, which are more common in the position of the opening structure such as the brim product, the instrument frame and the outlet.

03 Structure of diplomatic exchange

The intersection of external angles is generally divided into four categories greater than 90°, right angles, less than 90° and rounded corners, and diplomatic convergence structures can be found in all products, of which acute angles less than 90° are the most difficult to deal with, and attention should be paid to the design process to avoid this structure.

04 Internal intersection structure

Internal Angle intersection is generally divided into more than 90°, right Angle, less than 90° and rounded four categories, in all products can be found in the diplomatic structure, of which less than 90° acute Angle is the most difficult to deal with, such as the appearance of this structure as far as possible to enlarge the rounded corner, but also to avoid this structure of the block.

05 The plan meets the facade

The plane and the facade are nearly 90° intersection, which is more common in IP decorative panels and door handrails, and R-angle control will not cause problems. The edge of this structure should be set aside about 10mm covering range to prevent the edge covering effect from being affected by the structure. The specific structural parameters are introduced in the following section.

06 Elevation meets elevation

The facade is nearly 90° intersected with the facade, which is widely used in IP decorative panels, door panels, handrails and other certain products. If defined as cladding parts, stitches or vacuum forming parts are generally arranged. At the same time, the intersection surface less than 90° is also more difficult to deal with, pay attention to the B-side flanging without structural occlusion.

07 There is a gap in the product border

The boundary is in the shape of a broken line, with a straight line to a straight line, a straight line to an arc, etc.

08 There are suture classes

The stitching line is divided into whether it is arranged on the same horizontal plane, which is mostly not the same horizontal plane, and is widely used in handrails, upper trim plates and inlay plate products, and is a common structure.