Casescase

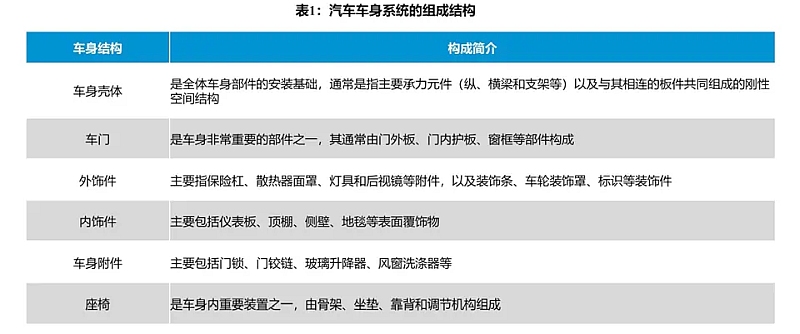

CasescaseThe car is generally composed of powertrain, chassis system, body system and electrical equipment four major systems, of which the interior and exterior trim is an important part of the body system. Auto parts according to the specific function of different, generally can be divided into powertrain, body system, chassis system and electrical equipment four categories. Among them, the body system is a space structure used to accommodate the driver, carry passengers and load goods, which mainly includes the body shell, door, exterior trim, interior trim, seat and body accessories.

Automotive interior and exterior trim has decorative, safety and functional characteristics. On the one hand, the interior and exterior trim parts play the function of the interior and exterior decoration of the body system, which is the embodiment of the automobile consumption attribute; On the other hand, the interior and exterior trim are closely related to the functionality and safety of the vehicle (for example, the main instrument panel carries the vehicle instrumentation and is closely related to the crash safety performance of the vehicle).

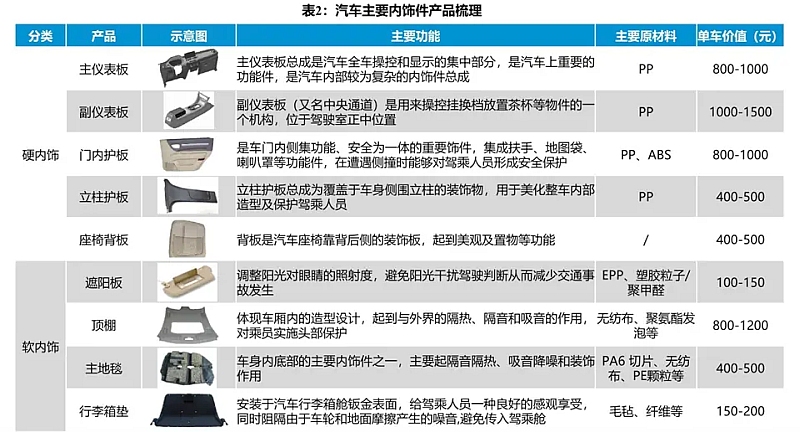

The interior parts are decorative parts covered in the interior of the car, which are beautiful and bear various functions. According to the product form, automotive interior parts can be divided into hard interior and soft interior. Hard interior parts mainly take injection molding as the core process, the main products include main and auxiliary instrument panels, door panels and column protection panels; Soft interior products mainly include sunshade, ceiling and main carpet.

Automotive exterior parts products mainly include front and rear bumpers. Automobile exterior trim parts are external parts connected to the car body through bolts or fasteners, which play a decorative and protective function of the vehicle, mainly including front and rear protection and grille.

Automotive interior and exterior trim parts are usually non-metallic materials, of which the amount of plastic ******. Plastic has the advantages of low density, corrosion resistance, good heat preservation, easy forming, etc., and is widely used in the manufacture of automotive interior and exterior trim parts. According to the material characteristics, plastics can be divided into thermoplastic materials and thermosetting materials; According to the use of materials, it can be divided into general plastics, engineering plastics and special plastics.

There are various manufacturing processes for automotive interior and exterior trim parts. According to the product characteristics of different internal and external decorative parts, different types of molding processing methods are usually selected, mainly including: injection molding, pressure molding, laminating, extrusion, blow molding, foaming, blister and boring.